Multiple numbering of Sebastian Erard harps: the case of harp(s) 1955 and 2116

- Lewis Jones

- Mar 7, 2019

- 20 min read

Updated: Mar 11, 2019

I hope it might be helpful to illustrate here the potential usefulness of the proposed pooling of harp numbers (see Request for information about multiple numbering of Sebastian Erard harps, 3 March 2019) by discussing further, as an example, the instrument which prompted my initial forum query and dialogue with Robert Adelson under the heading Erard double-action harp no. 1955 (Forum, 3-4 February 2019). This is another work-in-progress draft, offered here to encourage discussion.

This harp exhibits two numbers: 1955, stamped consistently on the woodwork, in places where it would not normally be seen; and 2116, conspicuously engraved on the right-side brass mechanism plate, as usual for Erard single-action instruments.

Numbering of the woodwork

The number 1955 is visible in at least four locations on the woodwork (see photographs in Forum, 3 February, and Blog, 3 March 2019); more than one metal stamp was used, having approximately these forms:

Neck: I955 H

Pocket piece: I955 / S / H

Shutter: F / I955

Pedalbox wall: I955

As some of the original woodwork of this harp is lost (parts of the pedalbox and of the upper part of the body, which have suffered woodworm damage, have been replaced), there may originally have been more than four instances of this number, and it is possible that further disassembly of the existing parts, such as removal of the mechanism from the neck, might reveal others.

The four-digit numbers appear always to have been stamped in one impression, using a compound stamp composed of separate metal number stamps which must have been held together in a brace (akin to composing letterpress type), whereas the separate letters (in this case 'H', in two forms, 'F' and 'S') were stamped individually. The London Erard workshops seem to have had both italic and upright serifed number fonts, in which the characters '1' and '0' were somewhat shorter than the rest. Although only a few letters of the alphabet occur, the letter font was slightly larger, upright and serifed, except for 'H', which lacked serifs and, varying in form (occasionally the horizontal line fails to meet one of the verticals), seems sometimes to have been executed by making three successive impressions with a chisel-like tool. If we posit that the set of parts for one harp – or at least that for a composite structure such as the pedalbox – was collated and numbered, probably on one day, from ready-made components in stock, and then fettled to fit together perfectly, the use of more than one stamp might indicate that more than one person was involved; perhaps various sets of number stamps, incidentally of slightly differing composition, were assigned to particular craftsmen or workshops. Note, in this example, the affinity in type form between two pairs: neck and pocket piece; and shutter and pedalbox wall.

As no other serial number occurs on the woodwork of this harp it is reasonable to conclude that the several parts were stamped while a coherent set of them was being collated in preparation for assembly – uniformity was not attained by chance. While some other Erard harps exhibit similar uniformity of woodwork numbering, other near-contemporaneous examples, also apparently coherent in their composition and not rebuilt, have been observed, in contradistinction to this, to exhibit more than one stamped woodwork number, thus indicating that uniform numbering was not an invariable practice in the Erard workshop(s). We can imagine ways in which, in the heat of the workshop, parts already stamped were occasionally rejected, damaged, swapped around, or regrouped according to the exigencies of manufacture. However, the possibility of later recomposition using parts from more than one existing instrument (considered below), of which there are analogies in the practices of nineteenth-century piano repairers, requires of us, in viewing these instruments at a distance of two centuries, a cautiously sceptical approach to the occurrence of more than one number in a single instrument.

Numbering of the mechanism in relation to numbering of the woodwork

Unlike, for example, the harp with serial number 2631 (the focus of the Munich symposium in November 2018), whose general integrity is not in doubt, that considered here has a complex history of damage and repair, which is incompletely evidenced by documents and the material fabric of the instrument. This very complexity makes it worthy of examination and discussion, and in its present impaired state, which has occasioned partial dismantling, the instrument invites access to areas which, in a well-preserved example, might be deemed inaccessible.

Context: Erard’s London business in 1814-15

In letter to Sébastien Erard sent on 17 January 1815, at about the time at which the wooden parts numbered 1955 would have been made, Pierre Erard wrote:

‘... One of Clementi's colleagues came to ask what discounts we would give them on harps, as they wish to send double actions to India. The arrangement you made with Chappell has been my guide, I gave them 25% and they give us credit for four months...’ (translated in Robert Adelson et al, The History of the Erard Piano and Harp in Letters and Documents 1785-1959, vol. 2, p. 581).

No time was wasted; within three weeks, the double-action harp serial no. 1948 had been dispatched to Clementi’s Cheapside emporium.

Regarding payment for this instrument, another letter from Pierre Erard to his uncle, dated 24 February 1815, mentions that ‘I did not have enough money to pay the two drafts, one accepted by Clementi & Co. for £86…’ (Adelson et al, ibid, vol. 2, p. 563). This sum might represent the agreed 75% of the normal full price of the harp; Pierre Erard’s letter to his uncle of 13 October 1815 mentions a somewhat greater reduction, by 30gns to 75gns [£78/15/-], this price being 71.4% of the full 105gns, offered ‘to teachers when the harp is for their use’ (Adelson et al, ibid, vol. 2, p. 615).

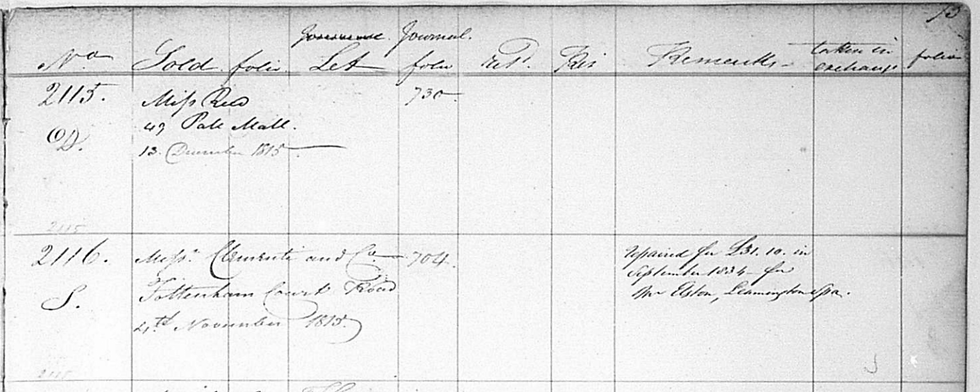

If the Erards were optimistic that trade via Clementi with India would flourish, they would seem to have been disappointed, but one further harp was sold to Clementi & Co. later in the same year: no. 2116. The single-action harp, designated ‘S’ [single] in the ledger, with the serial number 2116 was:

‘sold to Messrs Clementi & Co. / Tottenham Court Road / 4th November 1815’,

and it was later:

‘Repaired for £31/10 in / September 1834 for / Mr Elston, [of] Leamington Spa’.

On this occasion the harp was sent to Clementi’s Tottenham Court Road premises, the main manufactory, rather than to the administrative centre on Cheapside in the City. Number 2116 was clearly not part of Clementi’s India project; it had a single action, not double, and it is unlikely to have gone to India and then back to England, to be in need of repair in Leamington Spa by 1834.

Numbering, terminology and notation

It is assumed here that the serial numbers in the London ledger refer only to the engraved neck plate, and never to number(s) stamped on the wooden parts of the instrument during manufacture; and also, provisionally, in this particular case, that whatever Erard's 1834 repair operation entailed, the mechanism of no. 2116, as then referred to in the ledger, was essentially the same as was sold to Clementi & Co. 19 years earlier.

That the uniformity in numbering of woodwork (1955) observed in this harp sometimes extended also to the mechanism plate is shown by harps such as the double-action no. 1985 (c.1815; situated midway in the implied chronology between our numbers 1955 and 2116), in the Salvi Collection (illustrated in Roslyn Rensch, Three centuries of harpmaking (n.p. [USA]: Western Central, 2002), pp. 112-114), which is uniformly numbered on the neckplate and in other locations. I propose to call this UNITARY numbering and, because we need a convenient way to acknowledge the several parts of a harp, to adopt for it the two-part notation 1985(m)+1985(w), in which the mechanism number (m), also the ‘serial number’, precedes that of the woodwork (w).

Conversely, however, the wooden parts of several other Erard harps share a different number from the neckplate, again indicating variability in practice in the Erard workshops. Where there are two numbers, only one of them on the woodwork, I propose to call this BINARY numbering, of which the harp considered here is an example, written 2116(m)+1955(w). (It is possible that other numbers might lurk on wooden parts where they cannot be seen, but four occurrences should be enough to show that uniformity was intended.)

The notation proposed here has the potential to be extended to, for example, 1731(m)+1705+1738(w) (an example reported a few days ago), where the wooden parts exhibit more than one number (hence MULTIPLE numbering). In this particular case, there are four instances of 1705(w) (26 in advance of 1731(m)), widely distributed across the structural wooden parts, and a unique instance of 1738(w) (7 later than 1731(m)) on the removable pocket piece. It is telling that this small, removable component, installed at a late stage, after the mechanism was accommodated to the neck, should have a higher number than the mechanism itself. This plurality and inconsistency contrasts with, for example, the prevailing practice observed in the products of the Broadwood workshops – contemporaneously producing pianos on an even larger scale than Erard did harps – where an implicit rule of uniform numbering throughout an instrument was largely adhered to; when we find an exception to this now, it typically betokens alteration by a repairer. We might postulate that internal consistency of numbering was an ideal in Erard’s London workshops too – otherwise it would not have arisen – but that it was one which, for operational reasons, was not always adhered to.

The Sebastian Erard harp numbered 1955 and 2116 (2116(m)+(1955(w)): the existing material

After the repair documented in the ledger in 1834, the single-action Erard harp, serial no. 2116, does not reappear until 21 September 2011. (I would be very grateful for any information about the intervening 177 years!) Figure 4, an archived image from the Saleroom.com website, shows it as it was offered for sale then in East Boldon, Tyne and Wear, in the Fine Art and Antiques sale (lot 125: ‘A harp by Sebastian Erard, patent number 2116’) of Boldon Auction Galleries.

The wooden structure 1955(w) and neck mechanism 2116(m) were together at that date, and although the instrument was strung, it was structurally impaired. Owing to woodworm damage to the maple top-block of the body (this remained unchanged in 2016) and to the contiguous region of the curved body shell (this had partly been repaired by 2016), the upper part of the body was visibly distorted under the force exerted by the strings; and worm damage to the lower margin of the body shell and the rear of the pedalbox had apparently allowed the body as a whole to move in relation to the pedalbox, exposing a strip of bare wood. The vertical-grained slip of wood to the right of the neck knuckle was missing, exposing the pale maple wood of the treble end of the neck. In spite of the poor quality of the photograph, hints of gold-on-black decoration are just discernible. It has not been possible to trace the provenance of the instrument in the late nineteenth and twentieth centuries, or to identify who acquired it in 2011.

Fig. 5 shows the harp as it was offered for sale five years later via eBay, following an accident of damage, by a private owner in South London in June 2016. Although again strung, it was not in playable condition. In the intervening years, apparently soon after the 2011 sale, the harp had been repaired by an unidentified hand. When examined in 2016 an attempt had been made to reinforce the woodworm-weakened parts of the curved body shell, which had then been veneered externally and refinished in black. The decoration of the soundboard and swell shutters (gold and decoupage on black), however, is evidently original, and traces of bright gold leaf, recently (2018) found beneath the added veneer, indicate that the body shell, too, had not been refinished until after the 2011 sale. Comparison of the two photographs helps to distinguish between structural modifications made before 2011, apparently mostly in the second half of the twentieth century, and those made afterwards.

Before 2011: one feature visible in Fig. 4 is a horizontal line running around the semicircular rear wall of the pedalbox, which corresponds to a glued join between two superimposed layers of blocks, apparently salvaged from the shallower pedalboxes of two earlier single-action harps, from which the blocks between the pedal slots were still composed in 2016. The maker of the replacement wall did not, using recycled materials, attempt to replicate an Erard design: the modified pedal slots, for a single movement, extend right down to the bottom board (itself a mahogany replacement, presumably due to woodworm damage) and they are, unusually, closed at the top by a deep band of continuous wood. Although this work predates 2011, the use of epoxy resin and a synthetic filler indicates that it was executed after c.1950. Some of the composition decoration had been replaced using a related synthetic material, probably at the same date.

Between 2011 and 2016: the upper and lower ends of the body were repaired, using obviously modern materials, and the body shell was then veneered externally, completely covering what had remained of the original gold lines, and refinished in black paint. Among the more egregious modifications was the substitution of a broad mahogany board (uniform in thickness but tapering in width) for the lower three quarters of the length of the original internal bridge, the extreme ends of which (of beech) remained, firmly housed into the bottom chassis and the decayed top-block. It seems that until this intervention the soundboard had not been removed. Small missing parts, such as the cheek piece to the right of the neck knuckle, had been remade. In 2016 the harp, whose repair history had progressed down a declining gradient of competence, was not playable; although strung, it could not, due to the incomplete and discontinuous bridge, have been tensioned fully. The harp perhaps owes its survival to its perceived value as an ornamental object.

Initial interpretation

The original extant parts of the pedalbox wall (the two curved parts at the front, one stamped 1955 on its upper edge, and the left straight side) have the full 3 inch (76.2 mm) height characteristic of Erard's Grecian double-action harps; but because the original rear wall of the box, into which the pedal notches were cut, is missing, it is impossible now to tell whether the box originally accommodated single or double movement of the pedals. The wooden structure numbered 1955(w) is the earliest I have encountered with both a single action and the salient double-like features I identified (this Forum) on 4 February:

The pedalbox is 3 inches deep (significantly deeper than in Erard's pre-1815 single-action harps);

The neck has the same width and curve as that of Erard’s double-action harps of circa 1815;

The brass mechanism plates, also sharing the curve of Erard’s double-action harps, are wide enough to have accommodated two rows of fourchettes, the sliding nut pins being placed approximately where the upper (semitone) fourchettes would be in a double-action harp.

The existing 2116(m)+1955(w) composite (an example of binary numbering) might, if the two main components were together from the outset in 1815, be an example of the type listed in the Erard catalogue (Catalogue. Sebastien Erard, harp maker (London, c.1815) referred to by Robert Adelson (Forum, 4 Feb), under the heading ‘SINGLE MOVEMENTS’, as ‘The same shape as the Double Movement’; in which case it is – perhaps unsurprisingly – one such into which the double movement was not, at a later date, ‘inserted’ in substitution for the single one.

Sebastian Erard harp serial no. 1955

We should, however, consider the alternative possibility that Erard’s harp with the serial number 1995 originally had unitary numbering (i.e. that it was composed 1955(m)+1955(w)), which is consistent with its designation ‘D’ (double) in the ledger. (This is the putative harp about which I initially enquired on 3 February.) In this case the mechanism 1955(m) would have had to have been removed after manufacture and use, and it would, if it still exists, be elsewhere, as we know that the wooden parts 1955(w) are now coupled with 2116(m).

The harp no. 1955 was initially out on loan. Although the date of the start of the loan was not recorded, the harp was returned to the maker on 27 February 1821. While acknowledging as an improbable possibility Robert Adelson’s helpful suggestion (Forum, 4 February) that for Erard, ‘going out of their way to make the transition to the double action easier for their customers’, using the notation ‘“D” [Double] in the ledger […] was the simplest way to describe’ a single-action harp which, by design, might readily be upgraded into a double (i.e. that though single, the harp had almost all the characteristics of a double except a double action), there is a converse possibility, attested to when, ‘on 31 December 1822, Pierre Erard listed harp no. 1955 among the double-action harps for hire in the stock at Great Marlborough Street.’ It is just about understandable that 'D' was might have been written in the ledger according to an arcane company convention or even because the harp was mistakenly recognised by its general form rather than by checking its mechanism, but it is highly unlikely that Pierre Erard – to whom a double at this time was surely a more valuable asset than a single – would have listed a single as ‘D’, when to do so might have given rise to commercial embarrassment or disadvantage.

As outgoing loans and hirings were not invariably recorded in the ledger, we can’t be sure whether harp no. 1955 went out again for a short term, but we know that it was available to be sold on 11 February 1824 to a Miss Shearman of 73 Guildford Street, [London].

Possible scenarios

There are several possibilities. Although some perhaps seem more likely or appealing than others, it is not possible without further investigation absolutely to dismiss any of the following:

1. That 1955(w) and the single-action mechanism 2116(m) were, from the start in 1815, combined in the manufacturing process.

2. That a single-action harp (designated ‘S’ in the ledger) whose neck mechanism 2116(m) was engraved '2116', initially sold to Clementi & Co. in November 1815, was, when repaired by Erard for Elston in 1834, in such a state that its wooden parts were replaced, very largely or entirely, using those (1955(w)) of an existing instrument which were available.

3. That after 1834 (the year of Erard’s repair for Elston) and before 2011 (the auction in Boldon), another repairer fitted the single-action mechanism 2116(m) to the neck of an otherwise complete, or near-complete, existing wooden harp structure, consisting of all or most of 1955(w). This might, for example, have been justified had 2116(m) been in better condition than the mechanism already coupled with 1955(w). Given that some Erard harps at this time are uniformly numbered throughout (unitary) and that in others the mechanism and woodwork numbers differ (binary, etc.), we can only speculate, without tracing a mechanism numbered 1955, as to whether the extant 1955(w) was originally part of the harp no. 1955 in the ledger.

In scenario 1, the time taken to assemble and then to decorate the wooden components after numbering would account for an apparent time interval implied by the two serial numbers. Depending on how the chronology of numbering mechanisms related to that of numbering and assembling wooden parts, this might imply that the wooden parts had been available in the workshop for nine months or so before the harp no. 2116 was finished, later in 1815, and dispatched to Clementi in November. That the w and m numbers are as much as 161 apart, which is a greater interval than usual at that time, might indicate that the business was unsettled or – as I speculated in the 3 February Forum query – that the work being done at that time was in a sense experimental. Acknowledging that binary numbering was, as some but not all extant instruments indicate, an accepted practice, we should expect there to have been another harp (presumably double-action, because ‘D’ in the ledger) engraved on the neck plate with the serial number 1955 (i.e. 1955(m)+1xxx(w)). This latter would be the one which was, according to the ledger, initially out on loan, then available for hire, and was finally sold on 11 February 1824. This scenario is completely consistent with no. 1955 being designated ‘D’ and no. 2116 ‘S’ in the ledger.

In scenario 2, a harp comprising 1955(w) and – presumably, if not already removed – an unknown mechanism must have been available to the Erard workshop when, in 1834, Elston, who might but need not necessarily have been the purchaser from Clementi of the single-action no. 2116, presented his harp for repair. Elston paid a remarkably high price for the repair: £31/10/- [i.e. 30 gns] – the same as Erard (Catalogue) advertised for ‘introducing’ (i.e. substituting) the double movement into the neck of a single-movement harp designed from the outset to receive it. Presumably the principal cost of upgrading, by substitution, a wide-necked single-action harp in this way, in exchange only for a second-hand single-action mechanism, was that of making the new double-action mechanism. As the mechanisms were designed to be interchangeable, the new one could have been taken from the general run of production – it need not have been bespoke or exceptional. Other essential conversion work would have included remaking the rear pedalbox wall, local refinishing and redecoration to make good, and adjustment and regulation.

In the 1824 inventory of Jacob Erat's manufactory, ‘double machines’ were valued at £12/7/- and singles at only £4/15/- (these appear to be cost prices, not as they would have been marked up, perhaps by as much as 100%, for sale to a customer). As complete single-action harps were valued there at £30 and doubles at £40, a double machine represented about 31% of the total cost price of the harp. As Erard would have been able to draw on essentially the same London workforce as other established makers, it is unlikely that the actual cost to Erard of making a mechanism was much greater than to Erat. Allowing for Erard’s sale prices having been somewhat higher that Erat’s, £31/10/- for Erard’s planned-for conversion to double action seems to be proportionate.

Jacob Erat's records of repairs in the early 1820s, which are relatively detailed, giving the actual price to the customer, help us to estimate the extent of Erard’s repair for Elston. A complex repair in March 1824 for Mr Challoner of Regent St, for example, involving ‘making new sounding board to harp, repairing the neck, regulating back and bottom, new varnishing & ornamenting, and cleaning the machinery and pedals, new gilding bottom, body & neck, and stringing with 8 silver strings’, cost £15/-/-. As the actual cost of the wooden parts of a harp was relatively low, £31/10/- seems an appropriate price for Erard's providing, in effect, a complete used wooden harp (1955(w)) and reconciling it with Elston's mechanism (2116(m)).

Although the idea that replacing all of a harp except its neck mechanism constituted ‘repair’ of it is alien to us, it is possible, depending on the damage to Elston’s nineteen-year-old harp, that for Erard, focused on profitable manufacture, not on conservative restoration, the substitution of most of another instrument (one compatible because of similar age and neck design) was, economically and practically, the best course of action.

As Erard might in this scenario have combined variously numbered components in one new instrument (binary numbering), the harp with serial no. 1955 (that including 1955(m)) need not necessarily have been the one whose wooden parts were used in the ‘repair’. The nature of the task of accommodating the parts of the two instruments one to the other would have depended on whether 1955(w) was originally, in 1815, coupled with a single or a double mechanism. If, consistently with unitary numbering of no. 1955, 1955(w) was coupled with a double mechanism (i.e. 1955(m)+1955(w)), it would have been necessary in 1834 partly to remake the pedalbox, changing the notches from double to single movement; (the reverse of the corresponding change in 'upgrading'), but had 1955(w) originally been coupled with a single mechanism (which, due to the ‘D’ ledger designation of no. 1955 is consistent only with binary numbering of no. 1955), no major change would have been needed to the pedalbox.

In scenario 3, the most complex, Elston's harp, already repaired in unknown but presumably – noting the high cost – extensive ways by Erard in 1834, still identified by 2116(m), would have been combined with 1955(w) not at that time but in a later repair operation. Had 1955(w) originally been coupled with a double mechanism, which is consistent with the ‘D’ ledger designation of no. 1955 and unitary numbering of no. 1955 (i.e. 1955(m)+1955(w)), the more recent repairer would have had to change the pedalbox notches from double to single movement (as in scenario 2), unless such a modification had already been made. If executed after c.1950, this change could account for the existing single-movement pedalbox arrangement of 2116(m)+1955(w), in which the original semicircular rear wall of the pedal box of 1955(w), probably affected by woodworm, was largely replaced using existing parts reassigned from old single-action pedalboxes. Although rather crudely executed, this work was done by someone who had parts of other harps to hand, and it is conceivable that the same repairer combined 2116(m) with 1955(w). Although it might seem to us that to have changed at that time from double to single action was oddly retrogressive, the repairer might have wanted, for example, an instrument for a beginner to practise on, for folk music, or even as an ornament.

Alternatively, had 1955(w) originally been coupled with a single mechanism, which, due to the ‘D’ ledger designation of no. 1955 is consistent only with binary numbering of no. 1955, another explanation, such as decay or damage, would be needed for the late twentieth-century remaking of the pedalbox wall.

We should also acknowledge yet a further layer of complexity: it is conceivable that 2116(m) and 1955(w) were combined not in 1834 or when the extant pedalbox was last reformed, but in a separate operation, between 1834 and the late twentieth-century repair, adding another stage to the repair history.

Interpretation

Although in scenarios 2 and 3 the act of coupling 2116(m) and 1955(w) is essentially similar, in scenario 3 harp no. 2116 is subject to two or perhaps even three major repairs, the first by Erard (1834), leaving 2116(m)+1955(w) to be combined either in the late twentieth century or, if there were more than two repairs, at an intermediate date.

Given that some Erard harps at this time are uniformly numbered throughout and that in others the mechanism and woodwork numbers differ, we cannot be certain, without tracing a mechanism numbered 1955 (the subject of my initial query of 3 February), whether the extant 1955(w) is part of the harp numbered 1955 in the ledger. More numbering data are needed to be able to assess the proportions of instruments originally having unitary and binary numbering; and it is likely that those proportions varied from time to time.

The Erard catalogue of c.1815 shows that the similarity of neck form of the double-action and of a new class of single-action harps (originating, I suggest, about the end of 1814) was not only, as I envisaged in my initial Forum query (3 February), standardisation for reasons of efficiency; it was done by design, to allow the two mechanisms to be interchangeable, permitting the player to progress. Anecdotal accounts allude to relatively recent interchange of Grecian mechanisms, and of interchange in the past between English and French Erards. Where, for example, the w number is a thousand greater than the m number, a substitution has almost certainly taken place.

Unless a harp upgraded, as Erard envisaged, from single to double action is identified, we may never know how such instruments were (re)numbered. Significantly, though, Robert Adelson has, just as I was about to post this (4 March), drawn attention to the case of the double-action London harp no. 1377 (initially sold on 24 October 1811) which is documented in the London ledger as having been converted by Erard into a single-action, renumbered 2117. Although his conjecture that, if found, wooden parts of it would presumably be numbered 1377 could, if no. 1377 was made with a unitary numbering scheme, be correct, it is equally possible that if the numbering scheme was originally multiple (i.e. 1377(m)+13xx(w)) there might be no numerical trace, other than the new 2117(m) mechanism plate, of its having originally been no. 1377. Presumably a single-action upgraded to double-action would, according to this example, likewise have gained a new m number and, thereby, a new 'identity'.

The adjacency of the serial numbers 2116 (a single-action harp sold in late 1815 and repaired by the maker in in 1834) and 2117 (a double-action harp remade as a single-action a few years after 1811) is striking; it suggests that no. 1377 is likely to have been converted into no. 2117 at the end of 1815, as no. 2116 was being made anew.

Addendum, 9 March: A Scenario 4

Returning finally to Scenario 2 in the light of Robert Adelson’s observation concerning no. 1377 D becoming no. 2117 S: yet another possibility in 1834, suggested by the equal £31/10/- price for Elston’s ‘repair’ (ledger) and for upgrading single to double (Catalogue) is that Elston’s harp, which might have been recorded in the ledger in 1834 as ‘no. 2116’ because that was its numerical identity as it returned to the workshop, was upgraded to double action at the advertised price, and that this operation was concisely recorded in the ledger as ‘repair’. It is highly unlikely that, had Elston’s single mechanism perhaps failed and needed replacing in 1834 with the present single-action 2116(m), he would have been charged as much for a second-hand replacement single-action mechanism as for a new double one (compare Jacob Erat's ‘single machines’, which are valued at only 38% of his double ones). It is possible that the newly doubled harp (formerly known as no. 2116 S) then gained a new numerical identity (a number unknown to us) which was not recorded in the ledger in the same way as the renumbering (c.1815) of no. 1377 D as no. 2117 S had been. Although Robert has drawn attention to one instance of duplicate numbering (7 March 2019: quoting the newly found letter from Pierre Erard to Jean-Baptiste Erard of 1815), which was apparently an error, it is unlikely, bearing in mind renumbering of no. 1377 D as no. 2117 S, that Elston’s putative new double mechanism would have been freshly engraved with the old number 2116. In this case, our extant 2116(m) S, engraved in a style of 1815, not 1834, would have to be seen as the cast-off mechanism left in the workshop after the 1834 upgrade repair. Erard might then, to make good use of serviceable parts, have combined 2116(m) with 1955(w), the available wooden parts of another nineteen-year-old harp.

Without analysis of a substantial body of numerical data, including the mechanism and neck numbers as a minimum, supported by metadata for each instrument, such cases are likely to remain mysterious.

Acknowledgement: I am grateful to Mike Baldwin for allowing me to refer to and quote from his transcription of the Erat ledger: and to Robert Adelson for his stimulating flow of new documents and suggestions.

Addendum 9 March 2019: Sequence of numbers

I initially (7 March) proposed putting the w number(s) before the m number because, in several harps, the w number(s) are entirely or predominantly lower than the M, apparently indicating that it was common practice to combine a mechanism with wooden parts which had been made weeks or months earlier. However, as this is not a consistent pattern and it is more convenient to list instruments in serial (m) number order, as they appear in the London ledger and elsewhere, I have just reversed all the examples in the case study above and I propose m+w as the preferred order.

Dear Sam,

I suspect that the information you are looking for is to be found in the tremendous wealth of materials made available by the Centre Sébastien Erard, the research branch of the Gaveau-Erard-Pleyel archives, here: http://www.sebastienerard.org/en/

Dear Lewis,I will have a look tomorrow and let you know;By the way the serial number on my harp (2017) is under the first red string and the other writing indicated that its a french made model.I guess the serial number series is different from serial number series of the English made harps.I do wonder what the build date of mine is.

Dear Sam,

As a matter of interest, does your Erard Gothic have any visible woodwork numbers (please see my separate blog post about them) in addition to the serial number on the mechanism? So far I've collected information about woodwork numbers on slightly more than 30 Erard harps, which we will shortly publish here; but it would be good to have more. Best wishes,

Lewis.

Dear Sam,

Thank you for raising this, and for the photo of your Gothic harp. I'm afraid I can't read the number clearly. There are two main British Erard patents which pertain to the harp numbered 2116: patent no. 2016, Improvements in Pianofortes and Harps (1794), and patent no 3332 (1810), concerning the 'double movement'. Although the number on the mechanism plate follows the word 'Patent', it is, perhaps surprisingly, not a patent number but the unique serial number assigned to each instrument by the maker. This number was normally recorded in the company ledger (now preserved in the Royal College of Music, London) when each instrument was sold or hired. Best wishes, Lewis.

this page doesn't do pictures with text apparently so in reference to the picture I put up:Here is a picture of the serial number area on my Gothic Erard. You see the number 2017 in copperplate style under the red string